Highlights

- The Confederation of British Industry’s monthly manufacturing order book balance rose to +22 in September from +18 in August, its highest level since records started in 1977 (Reuters, 2021).

- Country’s ambition is to invest 2.4% of GDP in R&D and become a “Science Superpower. In Aerospace, every £1 of Government funding for R&D leverages £12 of private sector investment. (SMMT UK, 2021).

- According to The Digital Transformation Assessment produced recently by The Manufacturer and commissioned by IBM, 92% of respondents ranked ‘improving operational efficiency’ as their greatest priority (Production Engineering Solutions, 2021).

Key Developments

Focus on the future

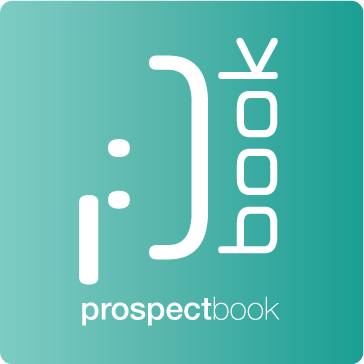

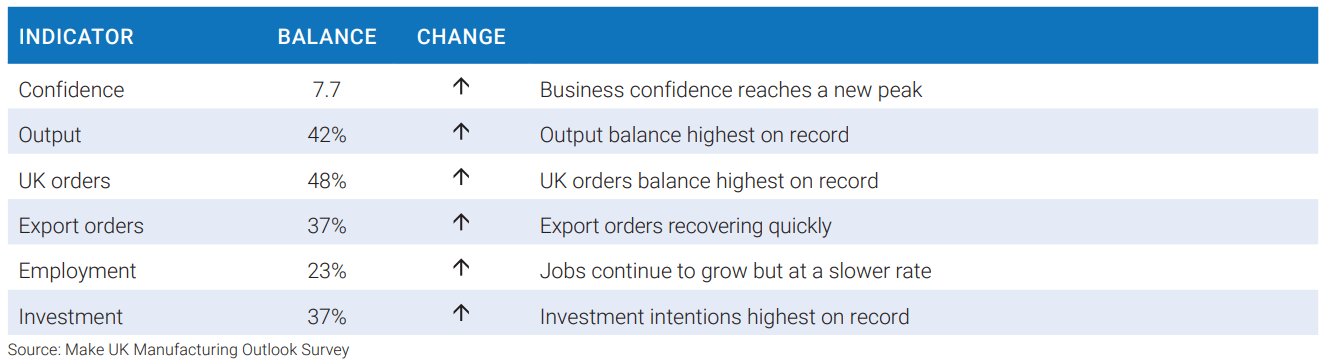

Following a series of sharp declines in output and orders in 2020, manufacturers have since indicated a swift bounce back as new work returned to unparalleled levels for many across the sector. Today, the pandemic appears to almost feel like a trove of the past, with many UK manufacturers focused on the future by investing in expanding capacity, innovating new products, and upskilling their workforce (Make UK, 2021).

Image source

Key segments plead for more state funds to boost sector

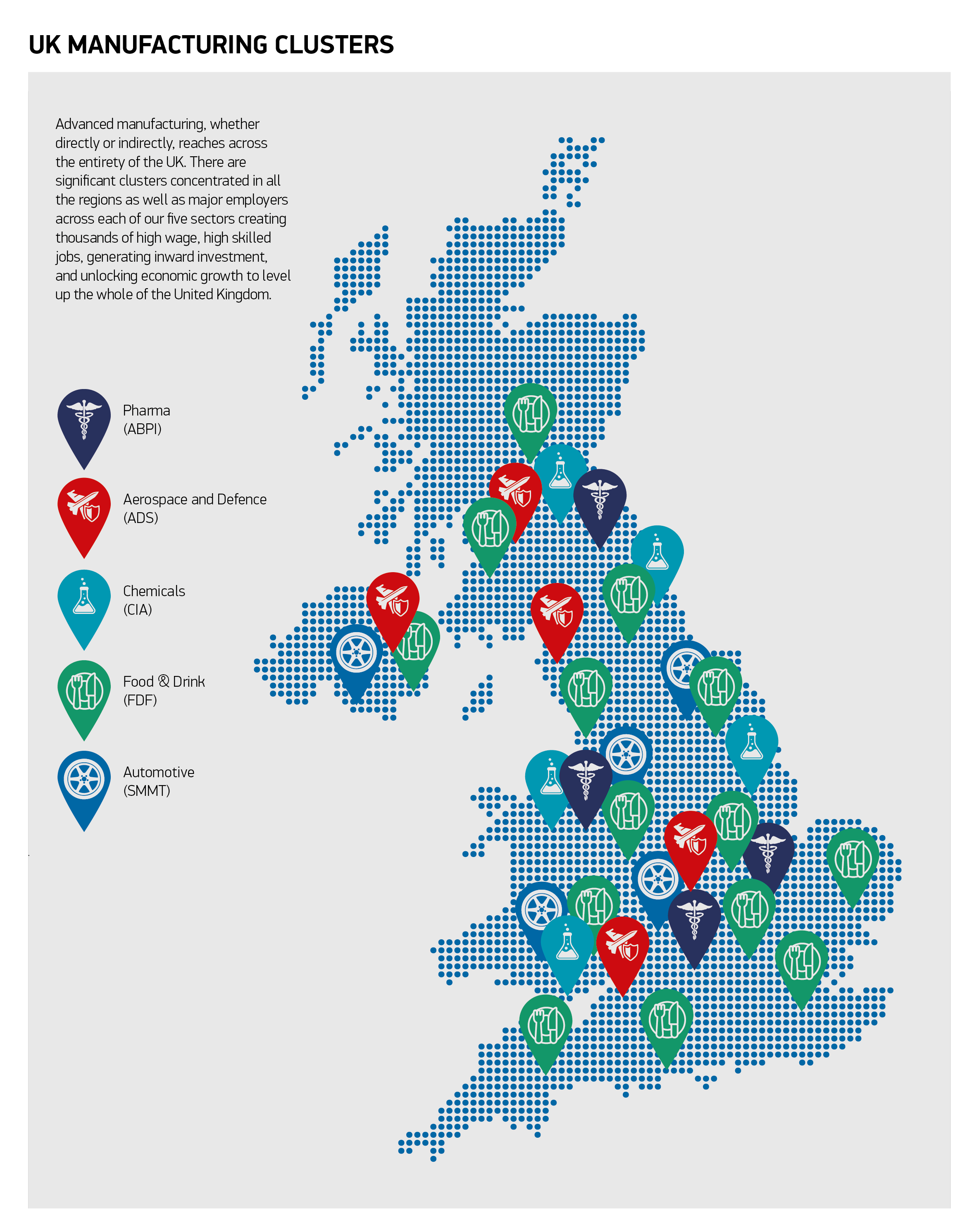

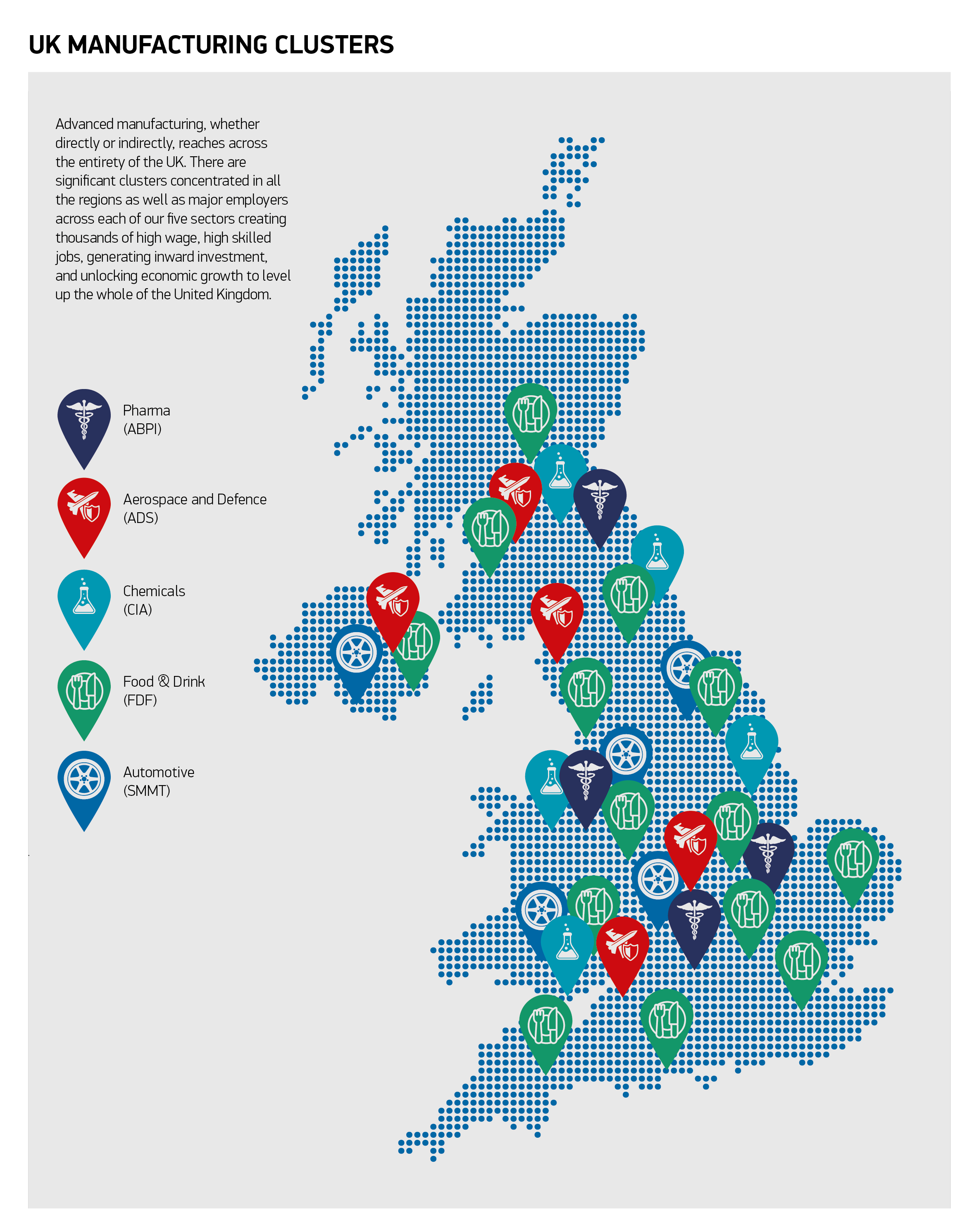

Five of the UK’s leading manufacturing industries (Auto, aerospace, chemicals, pharma and food and drink) have issued a plea for more government financial support to boost capital investment in research and development and new factories and equipment with lower carbon emissions.

The lobby groups said UK manufacturers needed help with energy costs, which can be as much as 80% higher than some European countries. The UK is in the midst of an energy supply crisis, with high prices hitting manufacturers’ ability to make up for earnings lost during the pandemic (The Guardian, 2021).

Digitisation is the key to operational excellence

According to The Digital Transformation Assessment produced recently by The Manufacturer and commissioned by IBM, there is long-term optimism around recovery. 2/3 of respondents said they were accelerating their investment in digital projects and putting people at the heart of the process who can act on ‘big’ data decisively and effectively. A further 92% of respondents ranked ‘improving operational efficiency’ as their greatest priority, suggesting that waste reduction and automated processes are likely to dominate the agenda in 2021 and indeed years to come.

Industry 4.0 is the continued need for the automation of traditional manufacturing that will take the industry to the next level. It is now well underway and will be sustained at pace over the next few years (Production Engineering Solutions, 2021).

A commitment to sustainable solutions and turbocharging UK manufacturing

COVID-19 has also brought significant worldwide attention to the climate crisis. The opportunities in the green/low carbon economy are tremendous and are likely to see considerable growth in the UK and internationally from 2021 onwards.

Early adopters can capture market share and develop know-how and expertise to tap into massive global markets and futureproof themselves, rather than locking in high carbon-emitting processes. Businesses that can take advantage of fiscal stimulus packages and pivot now rather than later will be at the forefront, not least because consumers (and employees) are demanding it.

Without solid commitment by energy-intensive manufacturers, it will be almost impossible to reach net-zero targets in the near to medium future. As a result, we are looking at a trend towards repurposing materials and resources, adopting renewable energy sources and reducing waste in the manufacturing process at every step (Production Engineering Solutions, 2021).

UK manufacturing holds key to unlocking Government’s domestic and global ambitions

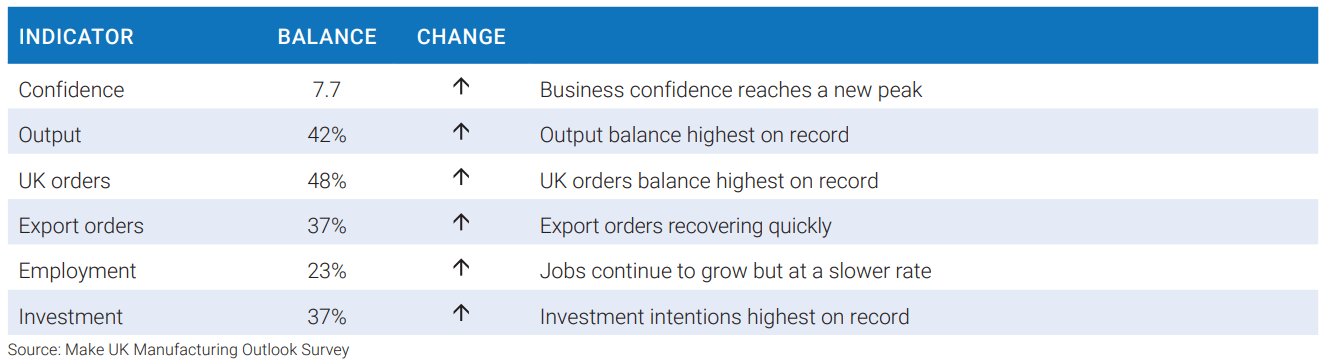

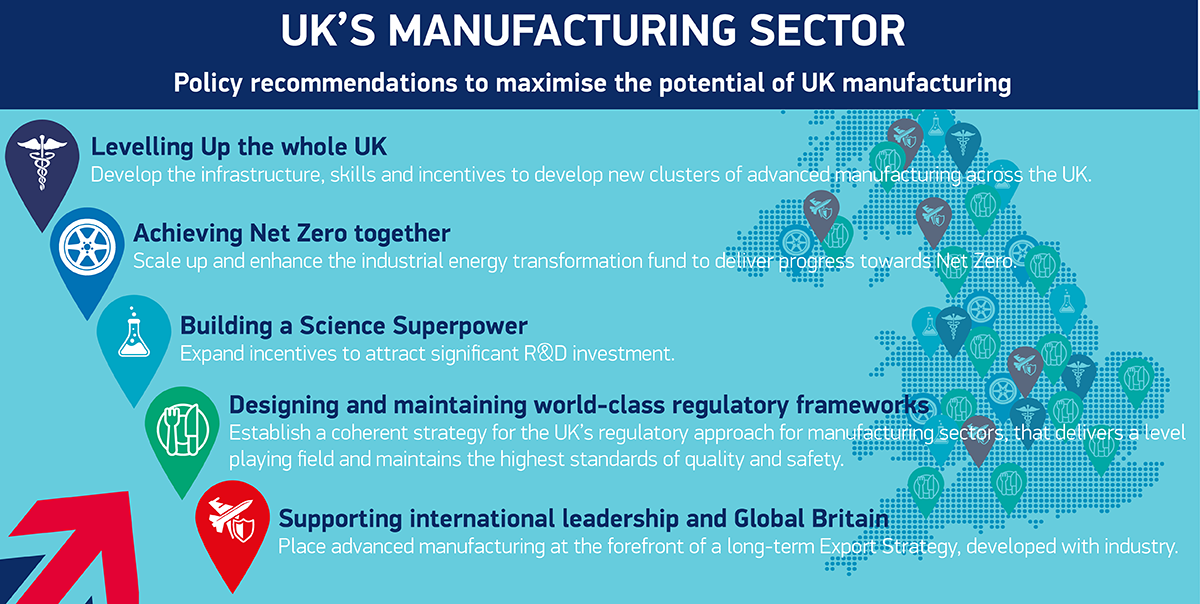

The success of the UK’s manufacturing sector will be central to Government’s ability to deliver on its national ambitions to level up the whole country, reach Net Zero by 2050 and become a global science super-power.

Five trade associations together representing sectors with nearly 800,000 employees, annual turnover of £338.2bn and £166bn in exports, published a joint report setting out policy recommendations to maximise the potential of UK manufacturing to generate and sustain high-value jobs and growth.

The Manufacturing Five – the Association of the British Pharmaceutical Industry (ABPI), ADS, the Chemical Industries Association (CIA), the Food and Drink Federation (FDF) and the Society of Motor Manufacturers and Traders (SMMT) – make recommendations on how Government can work with them to seize new economic opportunities, sustain jobs, and deliver growth and prosperity as we emerge from the pandemic.

Image source

This first joint report by the five associations sets out a long-term strategy that puts manufacturing at the heart of the UK’s domestic and global agenda to support the delivery of the Government’s five key ambitions (SMMT UK, 2021).

Image source

The recommendations:

- Levelling Up the whole UK

Recommendation: Develop the infrastructure, skills and incentives to develop new clusters of advanced manufacturing across the UK.

In 2019, manufacturing firms accounted for 58% of all R&D capital expenditure in the UK (£2.3bn). Encouraging investment in advanced manufacturing will be critical to the Government’s promise to level up the country. Investment would put the UK on a competitive footing with leading nations worldwide.

Long-established manufacturing clusters of excellence across the UK, such as automotive in the West Midlands, Clyde shipyards and chemicals in the Northeast, support region-wide supply chains and employment. The use of a long-term capital grant facility worth 10-15% of the value of investments could help attract significant new projects into clusters and beyond.

- Achieving Net Zero together

Recommendation: Scale up and enhance the industrial energy transformation fund to deliver progress towards Net-Zero.

Decarbonisation of product and production processes is a shared ambition across advanced manufacturing. While Government has set ambitious UK targets, this can only be achieved by a partnership with industry.

Complex manufacturing is energy-intensive, and it’s critical that the UK can compete to capitalise on emerging low-carbon opportunities, such as wind turbine blades, hydrogen and batteries. Energy costs and security are essential considerations for companies looking to invest in the UK, and electricity costs here are 80% above EU competitors.

Faster progress towards Net Zero would be achieved if the government incentivised industry to invest in radical decarbonisation solutions in the manufacturing process.

- Building a Science Superpower

Recommendation: Expand incentives to attract significant R&D investment.

Ambitions to invest 2.4% of GDP in R&D and become a “Science Superpower” require a partnership between Government and industry and targeted action.

Manufacturers are making critical investment decisions today that influence the next decade of investment. Government should expand incentives to attract R&D investment from industry, such as including capital as eligible expenditure under R&D tax credits and developing commitments to invest in R&D, securing new industry investment in the UK.

In just seven years, the modernisation of R&D tax credits would create 12,000 jobs and become a net revenue raiser for the Exchequer. By year 10, this would be adding £4bn a year to the economy. In Aerospace, every £1 of Government funding for R&D leverages £12 of private sector investment.

- Designing and maintaining world-class regulatory frameworks

Recommendation: Establish a coherent strategy for the UK’s regulatory approach for manufacturing sectors that delivers a level playing field and maintains the highest quality and safety standards.

Government should establish clear principles for ‘good regulation’ for the new UK regulatory environment. This should look to minimise costs to business and carefully consider any international, regional or devolved divergence which might impact competitiveness or risk creating barriers to trade with key trade partners. It should also only diverge domestically where necessary, or a clear advantage can be identified in partnership with industry.

- Supporting international leadership and Global Britain

Recommendation: Place advanced manufacturing at the forefront of a long-term Export Strategy developed with industry.

The UK’s advanced manufacturing sectors are recognised worldwide for high-quality, high-value production. They can both meet domestic demand and access global opportunities to the significant benefit of the national economy.

Government should create a globally attractive fiscal environment that supports and attracts manufacturing investment in buildings, plants, equipment and R&D.

In particular, business taxes should remain globally competitive, capital allowances and business rates should be more supportive for plants, machinery, and equipment. The scope of the patent box should be extended to cover a broader range of Intellectual Property (SMMT UK, 2021).